| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

Recommended

Print Settings:

Paper Size=Letter, Layout=Landscape, Margins=None, Scale=45%

|

M U L L I O N / A N C H O R C A P A C I T Y C A L C U L A T O R

|

FOR USE WITH FLORIDA PRODUCT

APPROVAL #21144, "ESTATE SERIES" MULLIONS

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

Mullion

|

Design

Pressure

(psf)

|

Min. Anchor/Clip

Capacity

Req'd (lbs)

|

|

| |

|

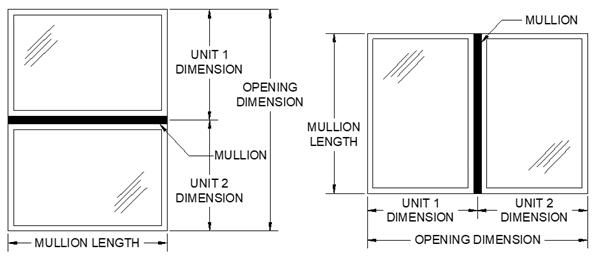

Enter Mullion

Length:

|

|

in

|

|

|

|

|

|

| |

|

Enter Unit 1

Dimension:

|

|

in

|

|

|

|

|

|

| |

|

Enter Unit 2

Dimension:

|

|

in

|

|

|

|

1

|

1"

x 2" x .125" Aluminum Tube Mullion

|

|

|

|

| |

|

Unit 1

& 2 Dimensions should include half of your mullion thickness.

|

|

|

|

|

2

|

1"

x 2" x .375" Aluminum Tube Mullion

|

|

|

|

| |

|

|

|

|

|

3

|

1"

x 2.5" x .125" Aluminum Tube Mullion

|

|

|

|

| |

|

Your Opening

Dimension is:

|

|

in

|

|

|

|

4

|

1"

x 3" x .125" Aluminum Tube Mullion

|

|

|

|

| |

|

Use only the dimensions of 2 directly

adjacent units.

|

|

|

|

|

5

|

1"

x 2.125" x .125" Aluminum Tube Fin Mull

|

|

|

|

| |

|

|

|

|

6

|

1"

x 4" x .125" Aluminum Tube Mullion

|

|

|

|

| |

|

Enter Loading Type (R or T):

|

|

|

7

|

1"

x 4" x .375" Aluminum Tube

|

|

|

|

| |

|

R = Rectangular or Point Loaded, T =

Trapezoidal/Triangular or Uniformly Loaded;

See "Load Areas" tab or approvals for examples. If unsure,

use Rectangular Loading.

|

|

|

|

|

|

|

|

|

8

|

2"

x 4" x .125" Aluminum Tube Mullion

|

|

|

|

| |

|

|

9

|

2"

x 6" x .125" Aluminum Tube Mullion

|

|

|

|

| |

|

Mullion Design Pressures and the corresponding Anchor/Clip

Capacity required are show in the table to the right. Choose a specific

mullion that exceeds your opening's Design Pressure.

|

10

|

2"

x 8" x .125" Aluminum Tube Mullion

|

|

|

|

| |

|

11

|

2"

x 4" x .25" Aluminum Tube Mullion

|

|

|

|

| |

|

Enter Mullion Type (1-19):

|

|

Design Pressure Required is:

|

|

psf

|

Load on Mullion Anchors/Clip is:

|

|

lbs

|

|

12

|

2"

x 6" x .25" Aluminum Tube Mullion

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13

|

3.25"

30 Degree Aluminum Bay Mullion

|

|

|

|

| |

|

|

Optional Design Pressure Reduction:

|

|

14

|

3.25"

45 Degree Aluminum Bay Mullion

|

|

|

|

| |

|

|

|

If your Mullion's Design Pressure is much higher than what your

structure's opening actually requires, you may reduce the Mullion's Design

Pressure. This lowers the anchor capacity required and could give you

additional anchor options or require less anchors.

|

|

15

|

2"

x 6" x .125" Aluminum Tube Mullion, 450

|

|

|

|

| |

|

|

|

|

16

|

2"

x 8" x .125" Aluminum Tube Mullion, 450

|

|

|

|

| |

|

|

Enter Reduced

Mullion Design Pressure:

|

|

psf

|

Your reduced

Anchor/Clip Capacity required is:

|

|

lbs

|

|

17

|

1" x 2" x .125" Aluminum Tube

Mullion, 238

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18

|

1" x 3" x .125" Aluminum Tube

Mullion, 238

|

|

|

|

| |

|

|

19

|

1" x 4" x .125" Aluminum Tube

Mullion, 238

|

|

|

|

| |

|

|

Mullions 1-14 May be used with any WinDoor product

as applicable.

|

|

| |

|

Knowing

Your Anchor Load Requirement, you can now choose the most appropriate Anchor

& Clip Type from the table below. See FL# 21144 "Estate" for

complete mullion installation instructions.

|

|

|

Mullions 15 & 16 are only to be used when

attached to a 450 Series French Door.

|

|

| |

|

|

|

Mullions 17, 18 & 19 are only to be used when

attached to a 238 Series Window.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Substrate:

|

3k Concrete

|

3.5k Conc.

|

Hollow or Filled CMU

|

Filled CMU

|

Wood

|

Metal

|

|

|

| |

|

Anchor Type:

|

3/16" DeWalt Ultracon+

|

1/4" DeWalt Ultracon+

|

5/16" Elco

Ultracon

|

3/16" DeWalt Ultracon+

|

1/4" DeWalt Ultracon+

|

1/4"

Elco CreteFlex

|

1/4" SS

DeWalt AggreGator

|

3/16" DeWalt Ultracon+

|

1/4" DeWalt Ultracon+

|

1/4" SS DeWalt AggreGator

|

#12

Steel Screw (G5)

|

#14

Steel Screw (G5)

|

#12 Steel Screw (G5)

|

|

|

| |

|

Edge Distance (in):

|

1"

|

2-1/2"

|

1"

|

2-1/2"

|

3-1/8"

|

1"

|

2-1/2"

|

1"

|

2-1/2"

|

2-1/2"

|

2"

|

1"

|

1"

|

2"

|

0.54"

|

0.60"

|

0.324"

|

|

|

| |

|

Embedment (in):

|

1-3/4"

|

1-3/4"

|

1-3/4"

|

1-13/4"

|

2"

|

1-1/4"

|

1-1/4"

|

1-1/4"

|

1-1/4"

|

1-1/4"

|

1-1/4"

|

1-3/4"

|

1-3/4"

|

2"

|

1-3/8"

|

1-3/8"

|

varies **

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

* Indicates that the Clip & Anchor

option does not meet the minimum capacity required for the mullion's required

Design Pressure. It may be possible to input the Min. Required Design

Pressure in the Optional Design Pressure Reduction section above to obtain

more favorable anchor/clip options. N/A indicates that the anchor's tested

spacing prohibits its use in this instance regardless of Design Pressure.

|

|

|

|

|

| |

|

|

|

|

|

| |

|

** For installation into metal, see the Approval

for metal type and thickness required.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|